Tracebility Standards Process In Quality Control Department Of Pharmaceutical Manufacturing

22 March, 2023

Orioled Hub is honored to be the Silver sponsor of the 39th Pharmaceutical Science and Technology Conference of Ho Chi Minh City University of Medicine and Pharmacy

10 April, 20231. Introduction

Solid dosage forms are the most frequently used drug delivery systems (DDS) for oral administration. They differ drastically in size and number of units administered as a single dose, including both single-unit dosage form (SUDF) and multiple-unit dosage form (MUDF). Multi-unit pellet system (MUPS) is one of the most popular MUDFs because of its unique advantages in physical properties (e.g., spherical shape) and mechanical properties (e.g., elastic and deformation ability and tensile strength). Usually, MUPS are filled into a capsule or compacted with excipients to form a tablet [1].

The main challenge in the production of MUPS is compression-induced damages to the functional coating, which leads to a subsequent loss of modified-release, taste-masking, or drug stabilizing properties. When functionally coated MUPS are used, the polymeric coating must be protected from rupturing during tableting because cracks in the coating may negatively impact the drug release properties. Therefore, pellet size, coating formulation, properties of tableting excipients, and compaction parameters must be carefully controlled to maintain the desired drug release properties of the pellets [1].

2. Benefits of multiple-unit dosage form over single-unit dosage form

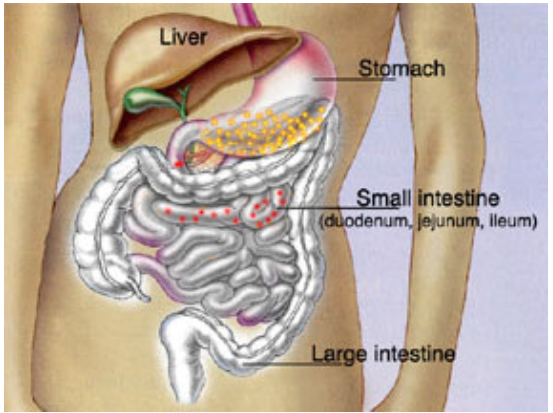

- Rapid yet gradual transit of pellets from stomach to intestines

- Short transit time in stomach reduces risk of premature drug release by attack of enteric coating

- The pellets spread uniformly throughout the gastrointestinal tract, reducing risk of high local drug concentrations and associated toxicity

- Low risk of dose dumping as dose is divided over many subunits

- Modified-release profiles can be obtained by simply mixing

pellets with different release characteristics [3]

Some MUPS products on the market are presented as follows:

| No. | Brand name | Drug content | Strenght | Manufacturer |

| 1 | Beloc ZOK | Metoprolol | 25, 50 mg | Astra Zeneca |

| 2 | Prevacid | Lansoprazole | 15, 30 mg | Takeda |

| 3 | Nexium MUPS | Esomeprazole | 20, 40 mg | Astra Zeneca |

| 4 | Losec MUPS | Omeprazole magnesium | 10, 20 mg | Astra Zeneca |

| 5 | Pentasa | Mesalazine | 500, 1000 mg | Ferring |

| 6 | Dexilant Solutab | Dexlansoprazole | 30 mg | Takeda |

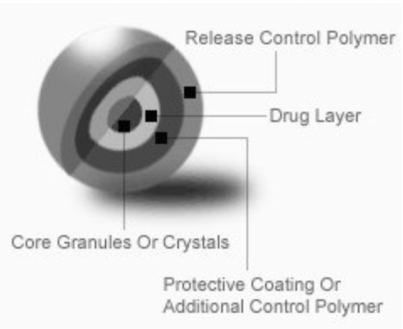

3. Construction of Multi-Unit Pellet Systems [3]

- Multi-unit tablet: Tablet containing pellets that are homogeneously distributed over the tablet mass.

- Each individual pellet has a spherical core containing (or coated with) the active ingredient(s) and has one or more protective coating layers to control drug release (e.g. sub coating, enteric coatings, sustained release coatings,…)

Typical composition of MUPS formulation

- Pellet/excipient ratio between 20/80 – 60/40 (w/w%)

- Average particle size:

- Pellets: between 300 and 1500 µm

- Excipients: between 100 and 300 µm

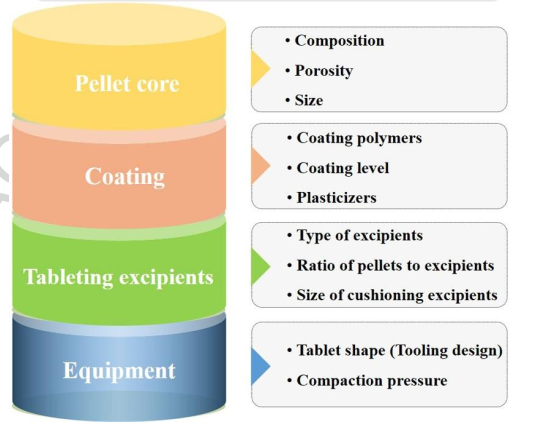

4. Factors that impact design of MUPS

4.1 Pellet core

The deformability of pellet cores influences pellet tabletability and rupture of functional coating layer during tableting. More rigid pellet cores correspond to smaller degree of deformation during compression, which is beneficial for maintaining the integrity of coating. Mechanical properties of cores depend on their compositions. Pellet cores made from microcrystalline cellulose (MCC) or sugar sphere have been widely used in MUPS

Pellet porosity influences the degree of pellet deformation and densification, which subsequently influences the compression of pellets and their release behavior.

The size of the pellet core can also affect both the compaction properties and the drug release from the compacted pellets. Therefore, larger pellet cores resulted in more damage to the coating and greater differences between the release properties of compressed and uncompressed pellets. Similarly, coated smaller pellets experienced a lower stress during compression because they can be more easily accommodated in the void of excipient matrix [1].

4.2 Coating

Coating level closely relates to film thickness and, hence, influences drug release behavior. Thus, drug release profiles can be modulated simply by controlling coating level. Increasing coating thickness could also make the coating layer more resilient to damages caused by compression. Although coated pellets with thicker films are more robust, drug release from pellets is also delayed. To overcome this problem, pore-formers, such as polysorbate 80 and HPMC , may be added.

Brittle coating films tend to rupture during compression and thus exhibit increased drug release. A common strategy to often coating films and increase their flexibility is to add plasticizer. Effective plasticizers should be compatible with polymers and reduce their glass transition temperatures [1].

4.3 Tableting excipients

One challenge in the development of MUPS is maintaining the desired drug release after compaction. In the tableting process, excipients are mixed with pellets as cushioning agents to prevent the direct contacts between pellets and, thereby, avoid or reduce the damage to coating films. It was estimated that approximately 29% of excipient is needed to fill the void space between densely packed pellets in tablet formulation [1].

Ideal tableting excipient should prevent the direct contact of pellets during compression. Another requirement of tableting excipient is to have flow property. The difference in the density of tableting excipient and pellets should be minimal to avoid the segregation during filling into compression press and maintain uniformity of dosage units. The protective effect of tableting excipient depends on the compressibility characteristics. Material that can deform plastically is the best excipient to use as tableting excipients [2].

4.4 Equipment

Tablet shape (Tooling design) directly affects stress distribution inside the tablet and influences the deformation of the tableting excipients during compaction. Biconvex tablet tooling inflicted less damages to the enteric-coated pellets in comparison with round flat-faced tooling.

Compression force applied for the tableting of pellets depends on the property of pellets. Some pellets have elastic recovery after compression, and such tablet has very low tensile strength. Compression force must be optimized for soft pellets to get desired tensile strength [1].

Reference:

- Tongkai Chen, Jian Li, Ting Chen, Changquan Calvin Sun, Ying Zheng, Tablets of multi-unit pellet system for controlled drug delivery, Journal of Controlled Release, (2017).

- Nrupa Patel, Sandipkumar Patel, Abhijeet Joshi, Multiple unit pellet system (mups technology) for development of modified release fast disintegrating tablets: a review, Journal of Pharmaceutical and Scientific Innovation, (2017).

- Wim Verbrugge, GEA’s integrated MUPS tableting system, (2022).